Introduction and Features of Automatic Tracking Filling Nozzles Liquid Filling Machine

With the continuous development of industrial automation, filling equipment is being increasingly used in the food, beverage, pharmaceutical, and cosmetics industries. The fully automatic tracking servo piston filling machine, as an advanced filling device, has become the preferred choice for many companies due to its efficiency, precision, and flexibility. This article will provide a detailed introduction to the working principle, main features, and wide range of applications of the fully automatic tracking servo piston filling machine.

1. Working Principle

The fully automatic tracking servo piston filling machine adopts an advanced servo control system, driving the piston for filling through a servo motor. The working principle is as follows:

-

Feeding System: Products enter the filling machine through the feeding system, usually including a conveyor belt, feeding pump, etc., ensuring the material smoothly enters the filling equipment. The design of the feeding system ensures continuous and stable supply of materials throughout the production process.

-

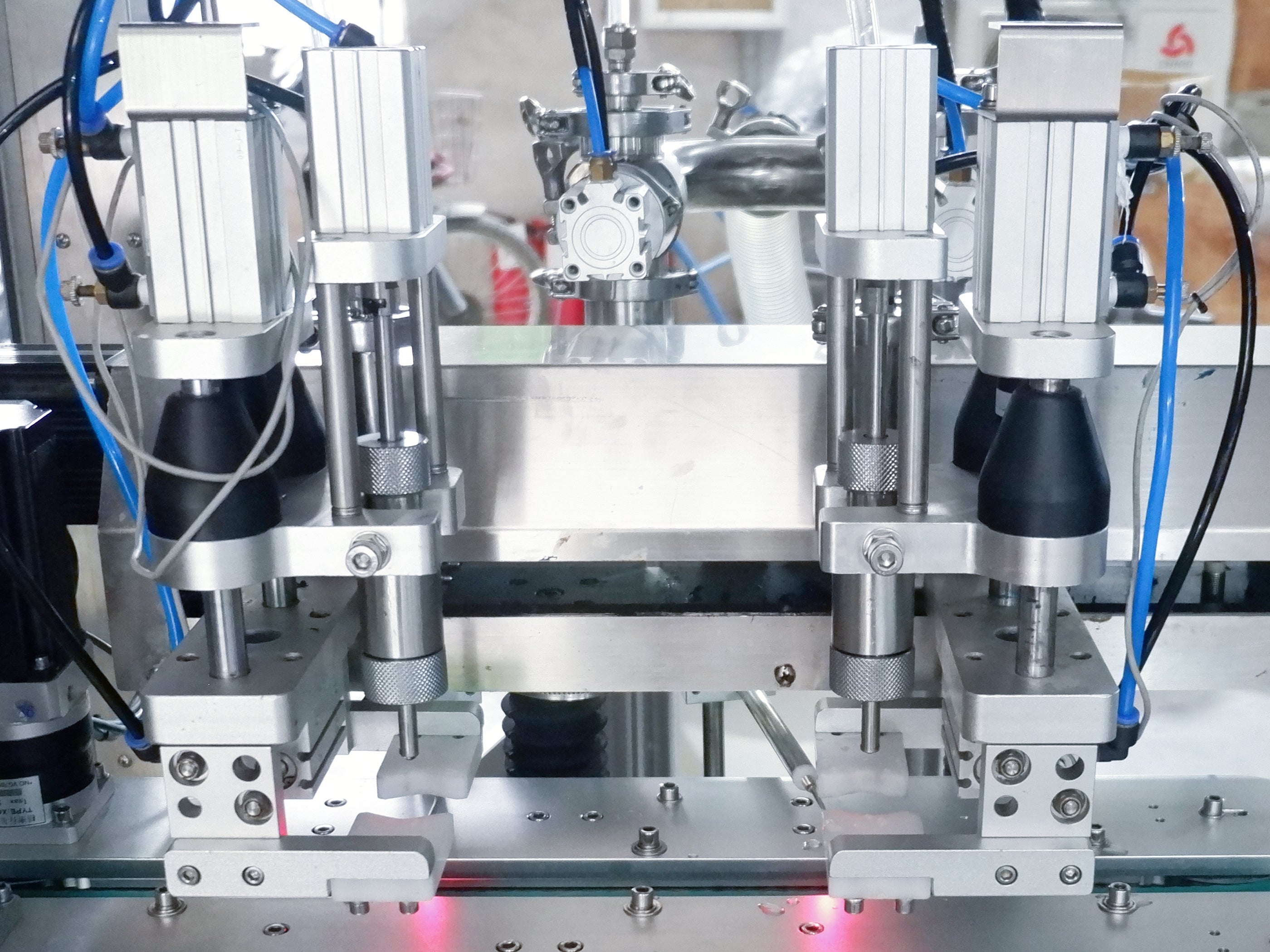

Filling Head Positioning: The filling head is precisely positioned according to preset programs under the control of the servo system. The servo system can adjust the position of the filling head in real-time based on the position and movement speed of the container, achieving synchronous tracking filling. This greatly improves filling efficiency and reduces downtime on the production line.

-

Filling Process: Driven by the servo motor, the piston performs precise filling according to the set filling volume. During the filling process, the filling head can move with the container, achieving dynamic filling and improving efficiency and accuracy. Both the filling volume and speed can be set and adjusted via a touchscreen to accommodate different products and production requirements.

-

Control System: The entire process is controlled by a PLC (Programmable Logic Controller), with operation conducted through a touchscreen human-machine interface. Parameter setting and adjustment are convenient and quick. The control system has a fault self-diagnosis function, capable of real-time monitoring of equipment operation status, ensuring safe and reliable production processes.

2. Main Features

-

High Precision: The servo control system ensures high precision in filling, with minimal error, suitable for products requiring high value and high precision. The high-precision positioning and control capability of the servo motor allow the filling machine to precisely control the volume of each fill, ensuring product consistency.

-

High Efficiency: The design of the tracking filling head allows the equipment to operate without stopping during the filling process, enhancing production efficiency. Hundreds to thousands of containers can be filled per minute. The high-speed response capability of the servo system makes the filling process smoother and reduces waiting time in the production process.

-

Flexibility: The equipment can be quickly adjusted according to different products and filling volumes, suitable for containers of various specifications and shapes. Whether it's small bottles or large cans, the fully automatic tracking servo piston filling machine can easily handle them. When switching products, simply adjust the parameters without complex mechanical adjustments.

-

Ease of Operation: The PLC control system and touchscreen human-machine interface make operation simpler, with intuitive parameter setting and fault diagnosis. Operators can master the use and maintenance of the equipment with simple training.

-

Hygiene and Safety: The fully automatic tracking servo piston filling machine is made of stainless steel, meeting GMP standards, easy to clean and maintain, ensuring product hygiene and safety. All components of the equipment are made of corrosion-resistant materials, maintaining good sanitary conditions over the long term.

3. Applications

The fully automatic tracking servo piston filling machine is widely used in the following fields:

-

Food Industry: Filling high-viscosity liquids such as sauces, jams, honey, and dairy products. The food industry has high requirements for the hygiene and precision of filling equipment, and the fully automatic tracking servo piston filling machine can meet these requirements, ensuring food quality and safety.

-

Beverage Industry: Filling liquids such as juices, concentrates, and drinking water. The beverage industry requires high speed and efficiency in filling, and the high efficiency and stability of the fully automatic tracking servo piston filling machine can significantly improve production efficiency.

-

Pharmaceutical Industry: Filling products such as liquid medicines, ointments, and disinfectants, which require high precision and hygiene. The pharmaceutical industry has extremely strict requirements for the precision and hygiene standards of filling equipment, and the high precision and easy cleaning characteristics of the fully automatic tracking servo piston filling machine can meet these strict requirements.

-

Cosmetics Industry: Filling liquids such as shampoos, shower gels, and skincare products. The cosmetics industry has higher requirements for the appearance and precision of filling equipment, and the fully automatic tracking servo piston filling machine can ensure the accuracy and consistency of the filling process, improving the product's appearance quality.

-

Chemical Industry: Filling industrial products such as lubricating oils, paints, and adhesives. The chemical industry requires filling equipment to be durable and stable, and the fully automatic tracking servo piston filling machine, made of high-quality materials, can operate stably for a long time, adapting to the complex production environment of the chemical industry.

4. Conclusion

With its high precision, high efficiency, flexibility, and hygiene safety, the fully automatic tracking servo piston filling machine has become an essential device for modern production enterprises to improve production efficiency and product quality. CX PACKING MACHINE is dedicated to providing high-quality fully automatic tracking servo piston filling machines, helping customers in various industries achieve intelligent production and enhance market competitiveness.

The fully automatic tracking servo piston filling machine not only improves production efficiency but also plays an important role in ensuring the consistency of product quality. Whether in the food, beverage, pharmaceutical, cosmetics, or chemical industry, CX PACKING MACHINE's filling equipment can meet the diverse needs of customers.

For more information about the fully automatic tracking servo piston filling machine or to order equipment, please visit our official website or contact our sales team. We are committed to providing you with professional consultation and services. CX PACKING MACHINE, your expert in intelligent production solutions.