What are the factors that affect the sealing quality of the automatic vacuum can sealing machine?

The factors that affect the sealing quality of the automatic vacuum canning machine are mainly the following:

Equipment performance and adjustment

- Vacuum system: The performance of the vacuum pump is crucial. If the vacuum pump speed is slow and the vacuum degree is insufficient, there will be too much residual air in the can, affecting the food preservation effect. In addition, if there is a leak in the vacuum pipe, the vacuum degree will also decrease.

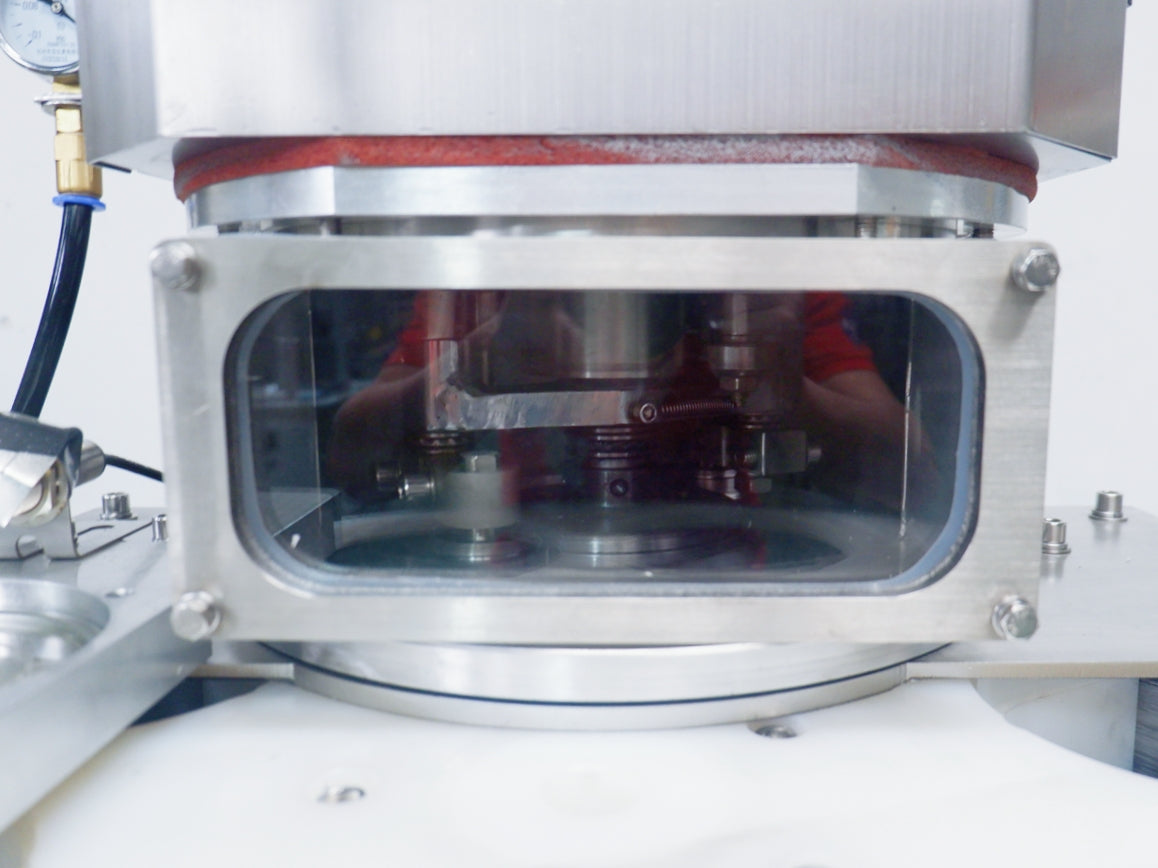

- Sealing roller: Its shape, dimensional accuracy and surface finish will affect the sealing quality. If the roller is worn or deformed, it will cause uneven and loose curling, false curling, curling "teeth" and other problems.

- Transmission system: If the transmission is unstable and the speed is uneven, the matching of the can cover and the can body will deviate during the sealing process, affecting the consistency and sealing of the seal.

Material quality

- Can body and can cover: The thickness, hardness and ductility of the material must meet the requirements. If the thickness is uneven and the hardness is not appropriate, it is easy to cause excessive deformation or loose curling during sealing. In addition, the quality of the round edge of the can lid is also critical. If there are defects or damage, it will cause a loose seal.

- Sealant: Its quality and performance directly affect the sealing effect of the seal. If the sealant is not sticky enough, aged or unevenly applied, it will cause a loose seal between the can lid and the can body, resulting in air leakage.

Operation and maintenance

- Operation parameters: Improper settings of parameters such as sealing temperature, time and pressure will make the seal loose and uneven. For example, too high a temperature will cause the packaging material to deform and the sealant to fail, while too low a temperature will not achieve a good sealing effect.

- Personnel operation: The operator's proficiency and sense of responsibility also affect the sealing quality. Improper operation, such as the can lid not being aligned with the can body, inaccurate placement, etc., will cause deviations in the seal.

- Equipment maintenance: Lack of regular cleaning, maintenance and repair of the equipment will reduce the performance of the equipment and affect the sealing quality. For example, if the sealing rollers and transmission parts are not cleaned and lubricated in time, it will cause increased wear and poor operation.