What Factors Mainly Affect the Accuracy of Labeling Machines?

The accuracy of the labeling machine is mainly affected by the following factors:

Mechanical structure factors

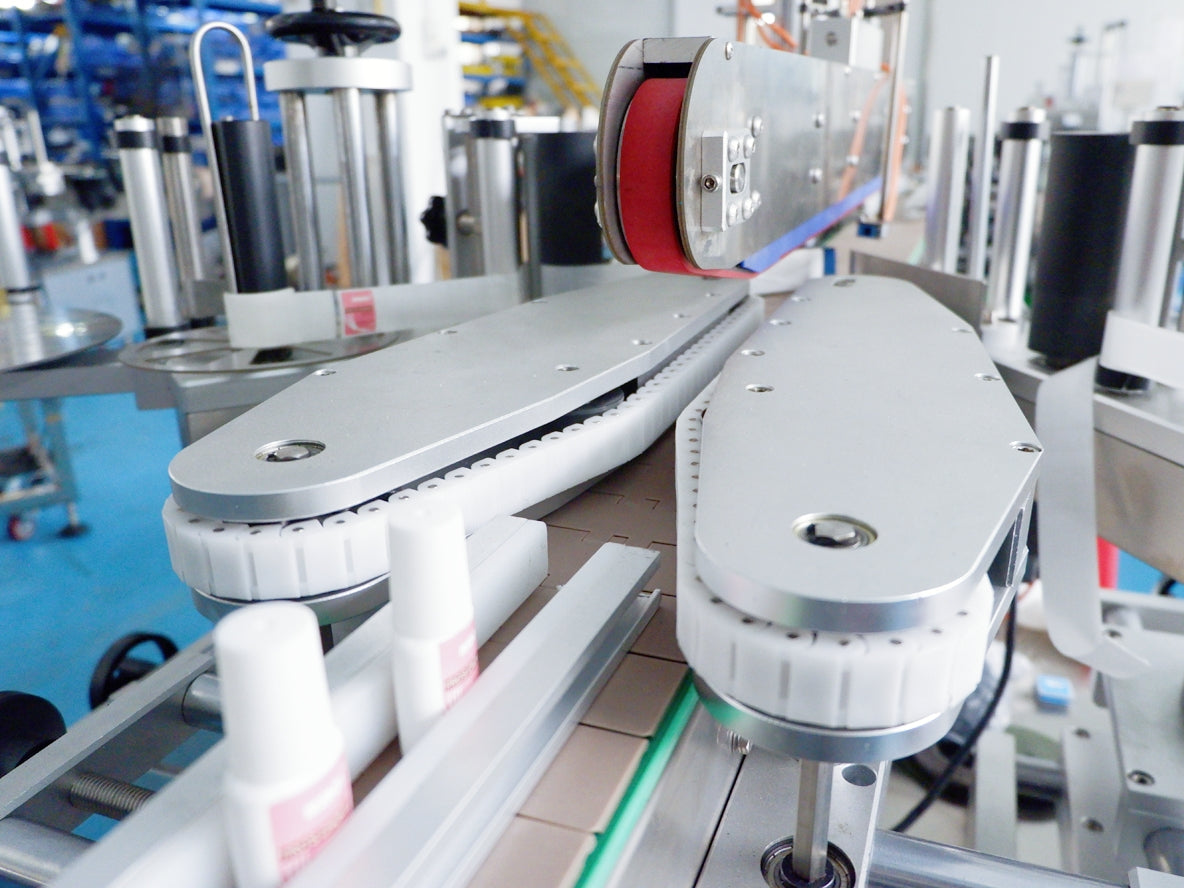

- Conveying system accuracy: The flatness and straightness of the product conveying track are crucial. If there is a deviation in the conveying track, the product will be offset during the conveying process, resulting in inaccurate label pasting position. For example, during high-speed labeling, a slightly uneven conveying track will cause the bottle to shake, affecting the labeling accuracy.

- Stability of the labeling head: The labeling head is the component that directly contacts the label and completes the pasting. The vibration of the labeling head during operation will have a negative impact on the accuracy. For example, unstable operation of the motor of the labeling head or loose mechanical connection will cause deviation in the labeling position.

Label and product characteristics

- Quality and size of the label: The dimensional accuracy and quality of the label are directly related to the labeling accuracy. Labels with inconsistent sizes, such as errors in length or width, will make it difficult to accurately control the labeling position. In addition, the material of the label also has an impact. For example, the flexibility of paper labels and plastic labels is different, and the requirements for labeling are also different. If the label itself is prone to curling or deformation, it will increase the difficulty of labeling and reduce accuracy.

- Product shape and surface characteristics: The complexity of the product shape has a great impact on labeling accuracy. For example, for irregularly shaped products, such as special-shaped bottles or products with curved surfaces and edges, it is more challenging to achieve accurate labeling than labeling on regular shaped products (such as cylindrical bottles). The smoothness of the product surface is also critical. A rough surface may cause the label to not fit tightly, bubbles or wrinkles may appear, and affect the labeling effect.

Sensors and control systems

- Sensor accuracy: The labeling machine relies on sensors to detect the position, speed and status of the product. If the sensor accuracy is not enough, such as being unable to accurately determine whether the product has reached the labeling position, or inaccurate detection of the label's remaining amount, it will lead to incorrect labeling timing.

- Control system accuracy: The control system coordinates the actions of the various components of the labeling machine based on the information fed back by the sensor. If the control system algorithm is not accurate enough, or if it does not respond in time when dealing with complex situations (such as product speed changes, label abnormalities, etc.), it will affect the labeling accuracy. For example, when the product conveying speed suddenly increases, if the control system cannot adjust the labeling speed in time, labeling deviation will occur.

External environmental factors

- Temperature and humidity: The temperature and humidity of the environment will affect the performance of the label and glue. In a high temperature environment, the glue may dry too quickly, resulting in a loose label; in a high humidity environment, the label may absorb moisture and become soft, affecting its dimensional stability and adhesion effect.

If you want to know more about labeling machines, please contact CX PACKING MACHINE - Guangzhou Chaoxian Packing Machine Co., Ltd., a professional manufacturer of labeling machines.