What Are The Processes Involved In Making Perfume?

The process of making perfume includes pretreatment, mixing, aging, freezing, filtering, coloring, bottling, and finished product inspection.

1. Pretreatment: The raw materials for making perfume, such as alcohol, essence, and water, must be pure and free of impurities. Therefore, they must be pretreated before use to ensure that the product has a clear appearance, a mellow smell, and a rounded aroma.

(1) Alcohol treatment: including purification and aging.

There are two commonly used methods for purification, namely, alkali reflux in alcohol and potassium permanganate oxidation. The purpose is to remove impurities. Add sodium hydroxide to alcohol, boil and reflux for several hours, and then distill once or multiple times to collect the purest part of its aroma for the preparation of perfume. Alternatively, add potassium permanganate solution to alcohol, stir quickly and let it stand, filter out the precipitate, and then add activated carbon. After leaving it for several days, filter it through silica gel to further absorb impurities. Add a small amount of fragrance to the purified alcohol and seal it at 15°C for several months, which is the aging process.

(2) Pretreatment of fragrance: Add a small amount of pretreated alcohol to the fragrance and use it after aging for 1 month.

(3) Pretreatment of water: Distillation or sterilization deionization. Sodium citrate or EDTA is usually used to remove metal ions.

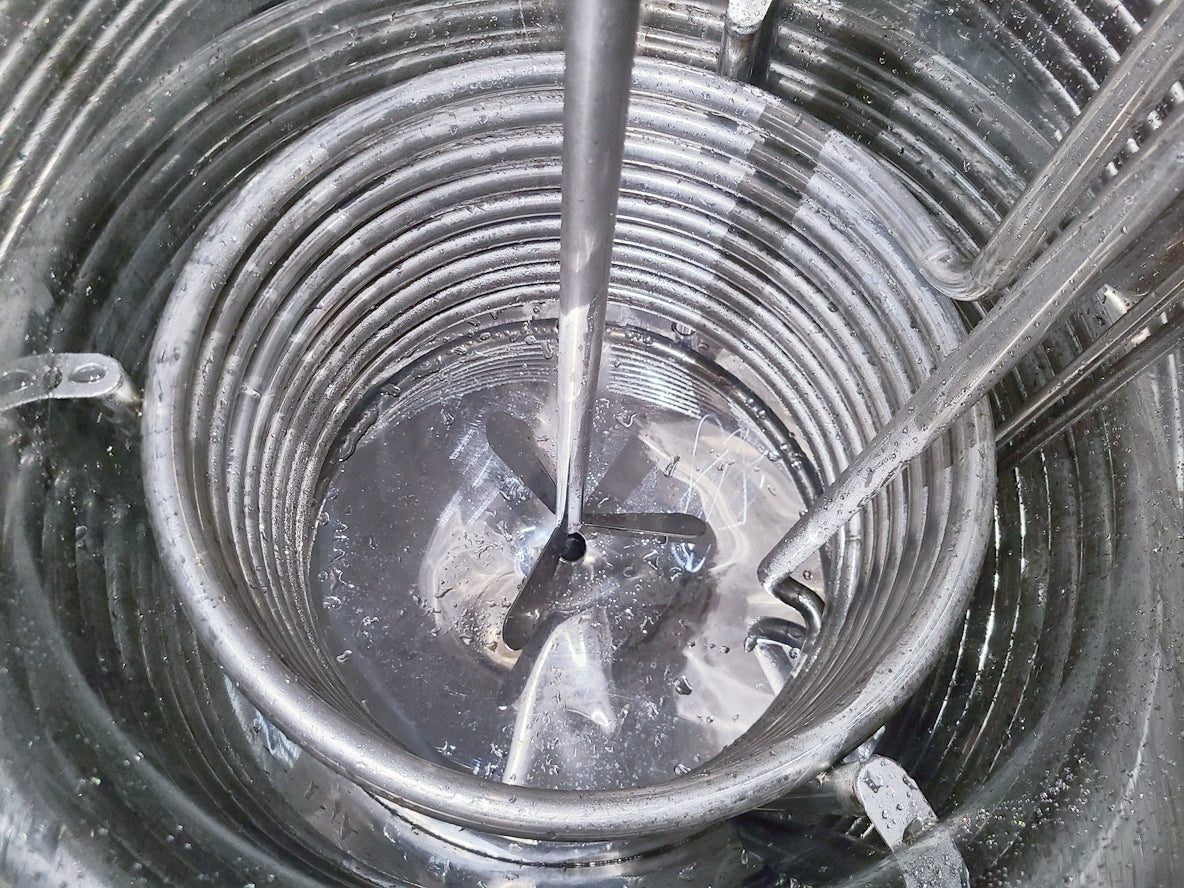

2. Mixing: Put alcohol, fragrance and water in a stainless steel or enamel, silver or tin container in a certain proportion, stir and mix for a period of time to allow the impurities in the fragrance to fully precipitate, which will improve the clarity of the finished product and the anti-turbidity under cold conditions.

3. Aging: Put the mixed perfume into a sealed container equipped with a safety valve for aging. There are two methods for aging perfume: physical and chemical. Physical methods include mechanical stirring, air bubbling, infrared, ultraviolet light irradiation, ultrasonic treatment, and mechanical vibration. Chemical methods include air, oxygen or ozone bubbling oxidation, silver or silver chloride catalysis, and tin or hydrogen reduction. During the aging period, the smell of the perfume gradually changes from rough to mellow and fragrant. However, if the fragrance is not properly blended, it will also produce an undesirable odor. As for the length of time required for aging, some people think it takes 3 months, while others think it should be longer or shorter. It can be adjusted according to production conditions and other factors.

4. Cooling: When the perfume encounters a lower temperature, it will become translucent or misty. If it is heated again, it will no longer be clear and will always be turbid. Therefore, the perfume must be frozen before filtering.

5. Filtration: After aging and freezing, some insoluble substances will precipitate out, and they must be filtered to ensure that they are transparent and clear. Filter press is used for filtration, and filter aids such as diatomaceous earth are added to absorb the precipitated particles, otherwise the precipitate will block the filter cloth pores. After adding the filter aid, the perfume should be cooled to about 0℃ and maintained at this temperature during filtration. The temperature of the filter press can be cooled by multiple cycles of the cooled perfume. After filtering out the precipitate produced by aging and cooling, it can be restored to room temperature and filtered through a fine-mesh cloth again to ensure that the product remains clear and transparent during storage and use.

During filtration, due to the use of filter aids, some spices may be adsorbed and cause aroma loss. This should be estimated in advance and compensated afterwards.

6. Coloring: Coloring is generally done after the filtration process, otherwise the color is easily adsorbed by the filter aid, but it must be added after color comparison with the standard sample.

7. Product inspection: Use instruments to compare color, measure specific gravity and refractive index, and use conventional methods to measure alcohol content, etc.

8. Bottling: The bottles should be washed with distilled water. When bottling, some space should be left at the bottleneck to prevent the solution in the bottle from expanding due to heat during storage and causing the bottle to break.

Do you know the process of making perfume? If you need packaging machines related to the production and packaging of perfume, please contact the professional perfume equipment supplier CX PACKING MACHINE - Guangzhou Chaoxian Packing Machine Co., Ltd., a professional manufacturer of perfume machines.