Desktop Automatic Round Bottle Labeling Machine

Basic use

Applicable to labeling on the peripheral surface of round bottles, single label, and double label. The space between the front and back labels can be adjusted flexibly. Disinfecting water and other industries. The optional peripheral positioning detection device can realize labeling at the specified position on the peripheral surface.

Optional ribbon coding and inkjet printers can be used to print the production date and batch number information on the label to achieve labeling-coding integration.

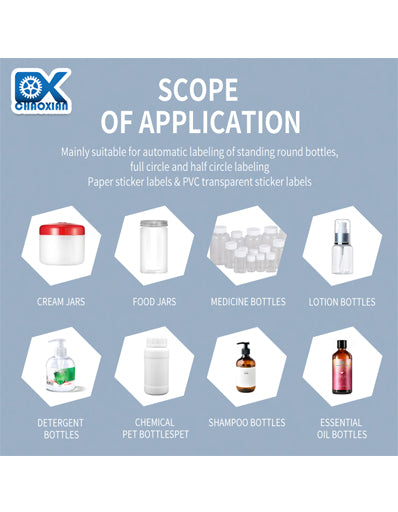

Scope of application

- Applicable labels: self-adhesive labels, self-adhesive films, electronic supervision codes, barcodes, etc.

- Applicable products: round bottles between 15mm ~ 120mm in diameter.

- Application industry: widely used in medicine, food, toys, daily chemicals, and other industries.

- Application examples: disinfection water bottle labeling, gel water double labeling, red wine bottle positive labeling, etc.

Automatic Plastic Protein Cans Label Pasting Round Bottle Labeling Machine with Date Printer

Machine Working Process

- Core working principle: Put the product on the conveyor belt, enter the bottle separating mechanism. After the bottle separating mechanism separates the product, the sensor detects the product passing and sends a signal back to the labeling control system. The control system controls the corresponding motor to send the label at the appropriate position. Attach the product to the labeling position and re-label at the same time. The labeling action of one label is completed.

- Operation process: put product conveyor belt (can be connected to the assembly line) —> product transportation —> product separation —> product inspection —> product positioning —> labeling and re-labeling —> collect the labeled products

Features

- Powerful, the same equipment can realize single labeling and double labeling of round bottle objects, and the space between the two labels can be adjusted flexibly. The optional circumferential positioning detection device can realize positioning and labeling function on the circumferential surface;

- The label has a high degree of coincidence. It is equipped with an upper pressing mechanism and a 3-axis positioning mechanism to prevent the bottle from fluctuating up and down and improve the labeling accuracy.

- Touch screen control, human-computer interaction interface with operation teaching function, parameter modification is intuitive and clear, and various functions are easy to switch;

- Intelligent control, automatic photoelectric tracking, with the function of no labeling, automatic calibration without the label, and automatic label detection function to avoid wasting labels and missing labels;

- Strong and sanitary, mainly made of stainless steel and high-grade aluminum alloy, with solid quality and meeting GMP production requirements;

- With an automatic shutdown function, production counting function, power-saving function (when there is no production in the set time, the device automatically switches to the power saving standby state), production number setting prompt function, parameter setting protection function (parameter setting management by authority) Facilitate production management

Technical parameters

|

Label Length(mm) |

20mm~ 300mm |

Label Width (backing paper width / mm) |

20mm ~ 170mm |

|

Product Diameter (for round bottles) and Height |

φ15mm~ φ120mm height: 25mm ~ 300mm |

Standard Labels Roll Outer Diameter (mm) |

φ300mm |

|

Standard Labels Roll Inner Diameter (mm) |

φ15mm ~ φ120mm height: 25mm ~ 300mm |

Labeling Accuracy (mm) |

± 1mm (excluding product and label errors) |

|

Speed of Labeling Head (m / min) |

5 ~ 45m / min |

Labeling Speed (pcs / min) |

25 ~ 35pcs / min |

|

Conveying speed (m / min) |

5 ~ 18m / min | Machine Net Weight(kg) | about 80kg |

| Frequency (HZ) | 50-60hz | Voltage (V) |

Single Phase 220V(can be made into 110V) |

| Power(W) | 200w |

Air pressure (Mpa) |

0.4-0.6mpa |

|

Machine Dimensions (length × width × height) |

1180*580*680mm | ||

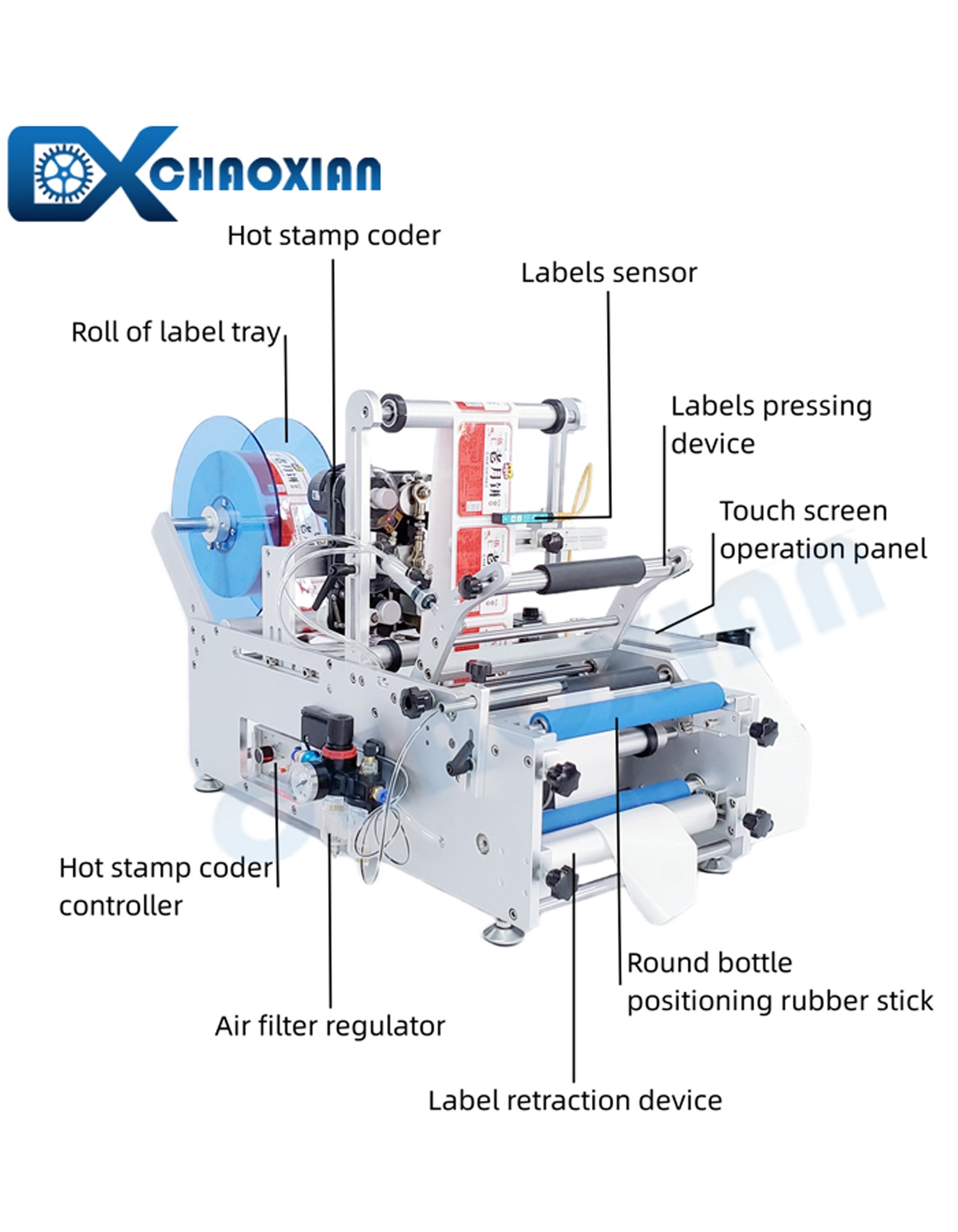

Optional functions of Automatic Plastic Protein Cans Label Pasting Round Bottle Labeling Machine with Date Printer

- Hot coding/printing function;

- Automatic feeding function (vertical bottle feeder);

- Automatic material receiving function (considering product consideration);

- Add labeling devices;

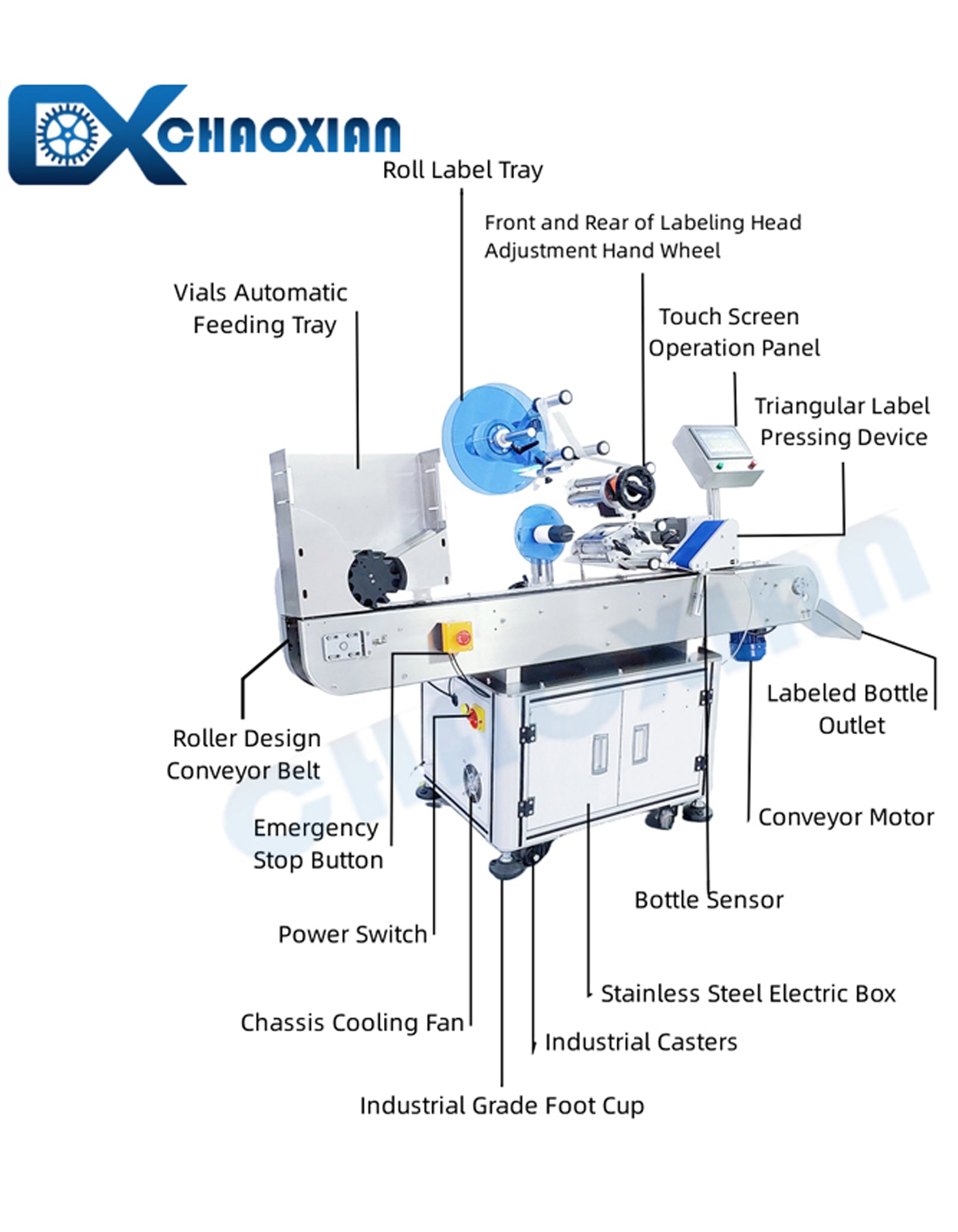

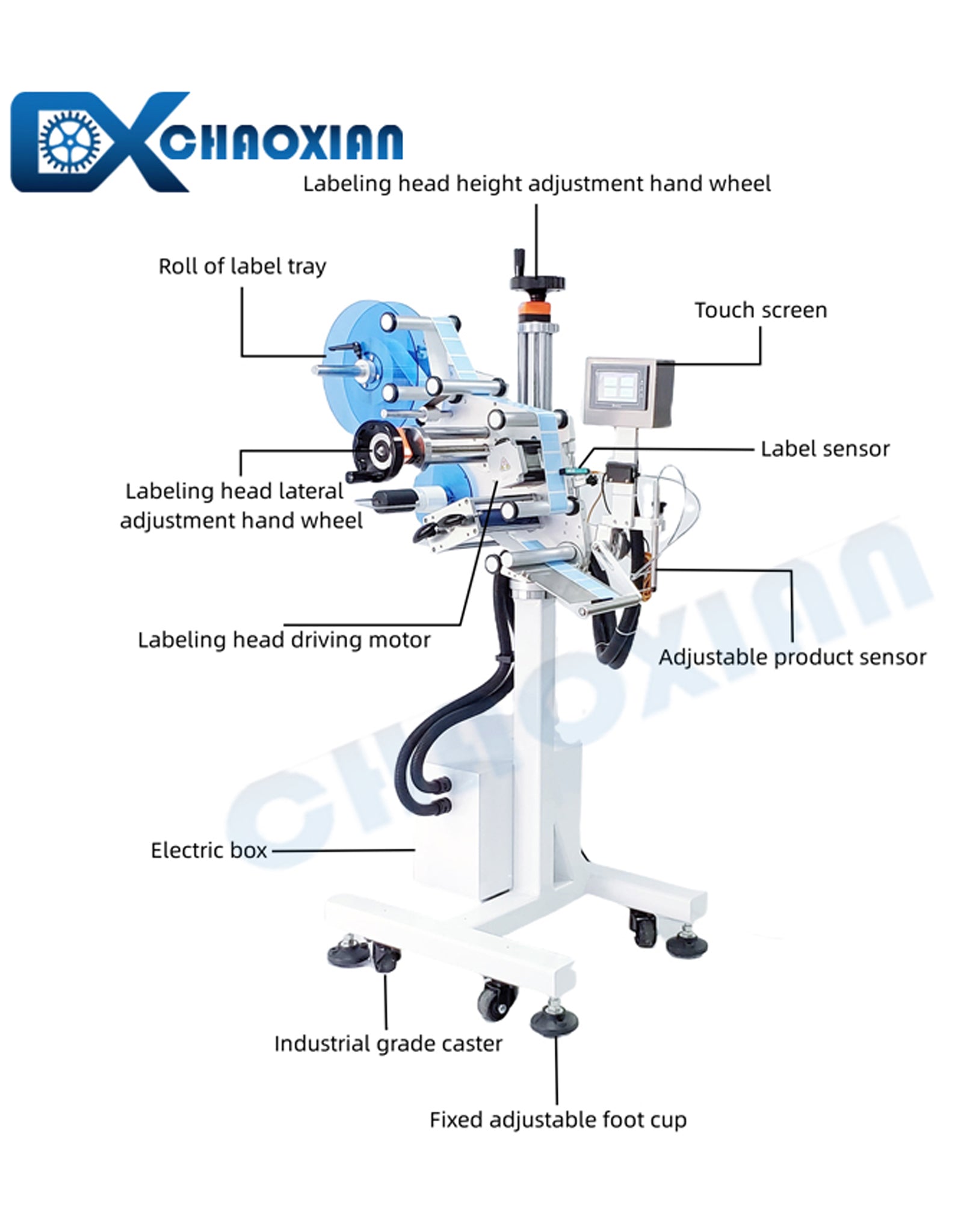

Machine Pictures