Automatic Vial Labeling Machine for Small Round Bottles and Ampoules – High-Speed Precision Labeler

Description:

This automatic labeling machine is suitable for labeling the circumference and semicircle of unstable cylindrical objects. It adopts horizontal transmission and horizontal labeling to increase stability and improve labeling efficiency.

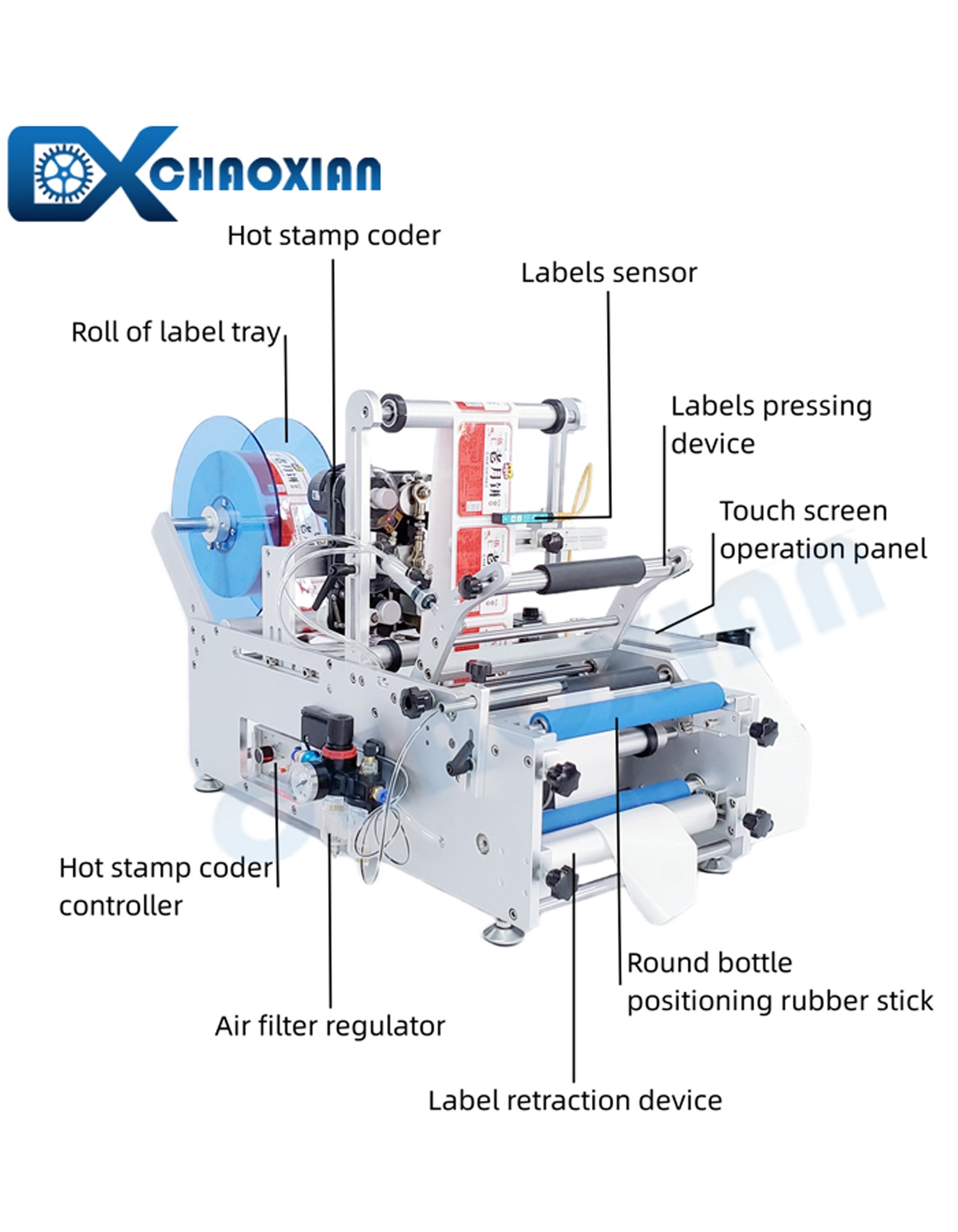

This labeling machine can be equipped with a coder or inkjet printer to the labeling head, which can print information such as production date, batch number and barcode on the label.

Working process

The core working principle of this automatic labeling machine: the automatic bottle separation wheel separates the products and automatically distributes them to the conveyor belt (or manually places the products). During the conveying process, the sensor detects the passing of the products and sends back the signal to the labeling control system. At the appropriate position, the control system controls the corresponding motor to send out the label and attach it to the product to be labeled. The product flows through the labeling device, the labeling belt drives the product to rotate, the label is rolled, and the attachment action of a label is completed.

Operation process

Place the product—>Separate the product and spread it in the middle of the conveyor chain roller—>Product conveying—>Product detection—>Labeling—>Labeling—>Collect the labeled products.

Main features:

1. High speed, using horizontal roller conveying mechanism, the conveying chain is tilted, the bottle is automatically guided, and the conveying labeling is stable. The labeling speed is as high as 200 bottles/minute, saving a lot of manpower and material resources;

2. Low bottle breakage rate, using flexible bottle separation technology and flexible labeling technology, bottle separation and labeling are smooth, and the bottle breakage rate is less than one in 100,000;

3. Excellent labeling quality, using label belt detour correction technology, high label head and tail overlap; rubbing and rolling labeling, flat labeling, no wrinkles, no bubbles, improve packaging quality;

4. High stability, Panasonic PLC + display touch screen + Sembcorp needle electric eye + American Hampson label electric eye composed of advanced electronic control system, support 7×24 hours high-speed operation of equipment;

5. Intelligent control, Automatic photoelectric tracking, with the functions of no labeling, automatic correction without label and automatic label detection, to prevent missing labels and label waste;

6. Sturdy and hygienic, mainly made of stainless steel and high-grade aluminum alloy, in line with GMP production specifications, with a solid structure and beautiful appearance;

7. It has fault alarm function, production counting function, power saving function, production number setting prompt function, parameter setting protection function, convenient production management;

Optional functions:

① Thermal coding/inkjet coding function;

②Automatic material collection function (considered in combination with the product);

③Automatic feeding function (customized according to customer requirements).

Application:

- Applicable labels: self-adhesive labels, self-adhesive films, electronic supervision codes, barcodes, etc. - Applicable products: small products that require labels or films to be attached to the circumferential surface or small conical surface. - Applicable industries: widely used in medicine, cosmetics, electronics, hardware, plastics and other industries. - Application examples: solid plastic bottle labeling, oral liquid bottle labeling, pen labeling, lipstick labeling, etc.

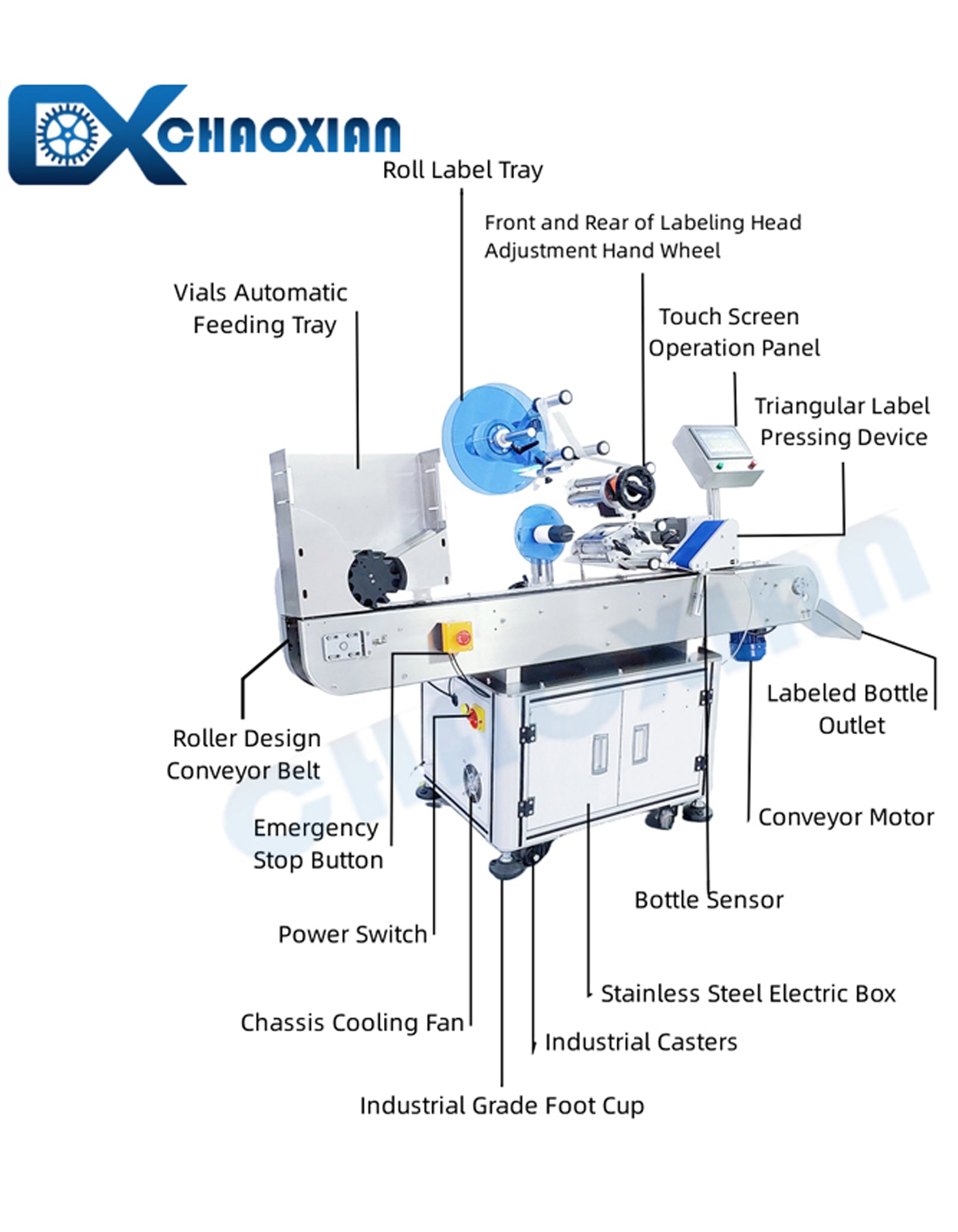

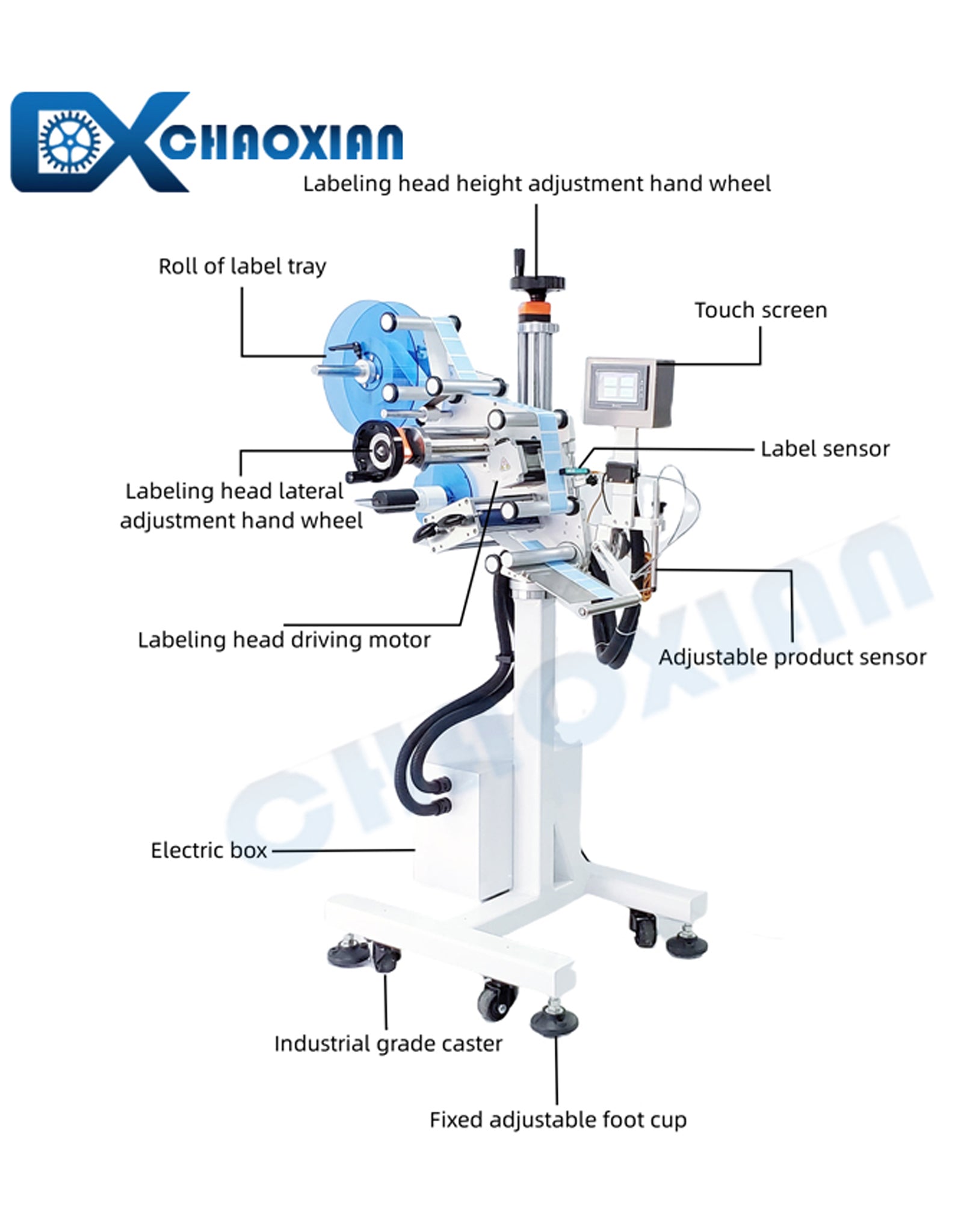

Structure Description of CX Automatic Vials Labeling Machine

Specification of CX Automatic Vial Labeling Machine

|

Machine Model

|

ALM-05

|

|||

|

Machine Name

|

CX Automatic Vials Labeling Machine

|

|||

|

Labeling Error

|

within ±1mm

|

|||

|

Applicable Product Size

|

Diameter from 10 - 30mm

Height: 20 - 120mm

(can be customized)

|

|||

|

Labeling Speed

|

60-200 bottles/min

(based on products size, bottle feeding speed)

|

|||

|

Label Szie

|

Length: 20mm-200mm

Width: 20mm~900mm

|

|||

|

Roll of Labels Outer Diameter

|

≤ 300mm

|

|||

|

Roll of Labels Inner Diameter

|

76mm

|

|||

|

Power Supply

|

Single phase 220/ 110V, 50/60Hz

|

|||

|

Power

|

1400W - 1600W

|

|||

|

Machine Size

|

About 2050*700*1400(L*W*H)

|

|||

|

Machine Weight

|

About 220kg

|

|||

|

Package Size

|

About 2150*8000*1600mm(L*W*H)

|

|||

Design drawing of CX Automatic Vials Labeling Machine

Size of CX Automatic Vials Labeling Machine

Details of CX Automatic Vials Labeling Machine

Real shots of CX Automatic Vials Labeling Machine